As people move toward cleaner transportation, hydrogen fuel cells are gaining popularity for automotive applications. But the technology has traditionally been hindered by issues of component cost and longevity, which have prevented it from gaining a firm foothold in the automotive industry.

Recently, a multi-disciplinary, multi-institutional group has identified a solution to both of these issues in a key fuel cell component — the catalyst used to drive the reactions. Their research was recently published in the journal Nature Catalysis.

The Washington University in St. Louis portion of the effort was led by Vijay Ramani, the Roma B. and Raymond H. Wittcoff Distinguished University Professor at the McKelvey School of Engineering, who served as a corresponding author for the study.

Hydrogen-oxygen polymer electrolyte membrane fuel cells (PEMFCs) electrochemically react hydrogen and oxygen, yielding electricity and releasing only water as a byproduct, making them an enticing alternative to gasoline or electric vehicles. The fuel cells typically use a platinum catalyst to speed up the reaction at the oxygen electrode, but platinum is expensive. The start-up and operation of the fuel cell also introduces side reactions that damage the efficacy of the catalyst.

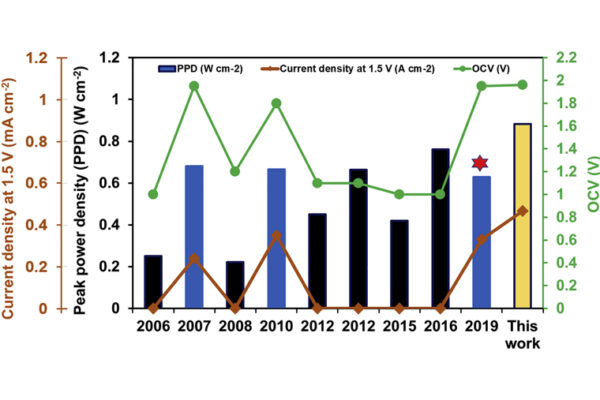

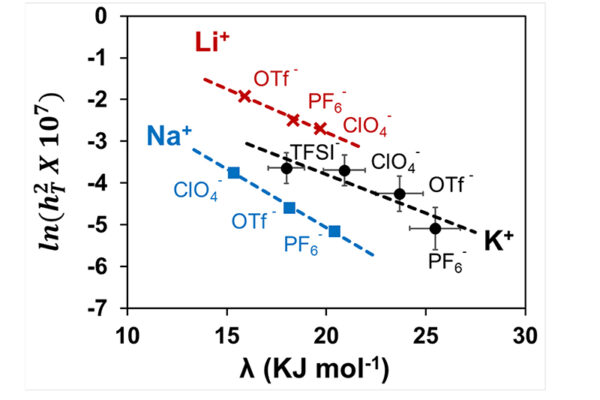

The research team demonstrated a high-performance platinum-group-metal free (PGM-free) catalyst that effectively resolves the twin issues of cost and durability. They synthesized a cobalt-nitrogen-carbon catalyst with an ultra-fine dispersion of catalytically active sites. They demonstrated that the catalyst approached the performance of state-of-the-art PGM-free catalysts and was four times as stable as the best PGM-free iron-nitrogen-carbon catalysts.

Ramani’s lab focused on testing these catalysts in real fuel cells. He and Cheng He, a doctoral student in his group, designed high-performance membrane-electrode assemblies and examined the catalyst’s performance when subjected to the rigorous stresses encountered in real-life use. The catalyst approached the Department of Energy’s (DOE) performance targets and exhibited the highest activity of all non-iron-based PGM-free catalysts.

Informed by detailed atomic level physical characterization and supercomputer simulations of the degradation mechanism, the team plans to further improve the activity and stability of this catalyst to rival and possibly surpass platinum in the near future.

The McKelvey School of Engineering at Washington University in St. Louis promotes independent inquiry and education with an emphasis on scientific excellence, innovation and collaboration without boundaries. McKelvey Engineering has top-ranked research and graduate programs across departments, particularly in biomedical engineering, environmental engineering and computing, and has one of the most selective undergraduate programs in the country. With 140 full-time faculty, 1,387 undergraduate students, 1,448 graduate students and 21,000 living alumni, we are working to solve some of society’s greatest challenges; to prepare students to become leaders and innovate throughout their careers; and to be a catalyst of economic development for the St. Louis region and beyond.

This research was supported by the US Department of Energy, Energy Efficiency and Renewable Energy, Hydrogen and Fuel Cell Technologies Office (DOE-EERE-HFTO) through the Electrocatalysis consortium (ElectroCat).