China expects to generate 2.5 billion end-of-life lithium-ion batteries from portable electronics such as smartphones and laptops in 2020, but very few are recycled. Although these batteries are discarded, the metals inside them are still valuable.

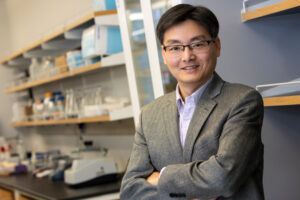

A team of researchers, led by Zhen (Jason) He at Washington University in St. Louis, is developing a method to recycle the batteries’ materials to reuse their valuable compounds. He, professor of energy, environmental and chemical engineering in the McKelvey School of Engineering, and colleagues at Shanghai Jiao Tong University in China and at Virginia Polytechnic Institute and State University conducted a feasibility study for electrochemical “refilling” of lithium-ion batteries into the spent electrodes to regenerate useful compounds, such as lithium cobalt oxide.

Results were published as the supplementary cover story in the Aug. 10 issue of ACS Sustainable Chemistry & Engineering.

Spent lithium-ion batteries contain valuable metals, such as lithium, cobalt, nickel, copper, aluminum and iron, as well as toxic materials such as lithium hexafluorophosphate and polyvinylidene fluoride. Lithium is a critical mineral resource with a limited reserve, so recycling the material may address the shortage as well as minimize environmental pollution.

“Since 95% of the materials are still there and usable, we wanted to see if we could regenerate the complete lithium cobalt oxide compounds directly instead of recovering individual elements and then putting them together to be a useful compound,” He said. “We used an electrodeposition process where we deposited the lithium ions on the waste electrodes driven by the electricity that creates the electric field to absorb the ion onto the electrode.

“We can add an additional amount of lithium-ion into the waste electrode, and you get a complete formula that allows you to reuse those materials.”

Because the batteries are inexpensive, there is little incentive to recycle, so only about 5% of lithium-ion batteries are recycled, He said. However, recovering and recycling critical elements such as lithium will play a key role in the sustainability of resource use by society, He continued. Other researchers have tried various methods to recycle the materials, including extracting the materials separately through mechanical methods. But these methods require additional reagents and can generate secondary pollutants.

With the successful results of this feasibility study, He and the team plan to continue efforts to regenerate the materials in lithium-ion batteries and study its cost-effectiveness.