Sang-Hoon Bae, an assistant professor of mechanical engineering and materials science, and Mark Lawrence, an assistant professor of electrical and systems engineering, both at the McKelvey School of Engineering at Washington University in St. Louis, are undertaking projects to transform computing through developing next-generation technologies.

Bae’s work focuses on integrating 2D elements into advanced 3D microelectronics. Lawrence will enhance artificial intelligence (AI)-driven machine vision systems to achieve real-time adaptivity and high energy efficiency in a range of applications.

Bae and Lawrence each received a grant from the National Science Foundation (NSF) as part of a $45.6 million investment into 24 research and education projects. The projects are supported by funding from the CHIPS and Science Act of 2022 and by the NSF’s Future of Semiconductors program. The program aims to accelerate the growth of a U.S.-based workforce and knowledge that will enable innovative semiconductor and microelectronics development.

Versatile in-sensor machine vision

Machine vision systems enable computers to emulate the human ability to understand and interpret images and video using cameras, sensors and specialized software. Lawrence — along with project lead Xuan “Silvia” Zhang, at the University of Massachusetts Amherst and incoming associate professor at Northeastern University, and collaborators from the University of Illinois at Urbana-Champaign and the University of Rochester — received a $2 million grant to build machine vision systems capable of solving specific image sensing problems with extreme accuracy and unprecedentedly low power consumption.

Instead of developing better cameras, the team plans to harmoniously tailor every layer of the imaging stack to the application at hand, from the optics and the in-sensor electronics to the image processing algorithm. This will enable them to turbocharge AI-enabled machine vision hardware and satisfy the tremendous computational demand that arises from modern data-heavy applications ranging from quality control and inspection processes to robotics and automation.

“Our approach draws inspiration from the human visual system and is profoundly shaped by recent developments in AI-driven machine vision,” Lawrence said. “We aim to create the scientific and engineering foundations for vertically integrated machine vision systems cutting across optics, image sensors and vision processors. We are excited to apply this paradigm to urgent problems including the development of low-latency, real-time, autonomous driving perception capable of adapting to environmental conditions without the need for powerful on-board computation, and remote, persistent, environmental monitoring enabled by near-zero power, event-driven smart sensors.”

In partnership with the UMSL/WashU joint engineering program, Southern Illinois University Edwardsville, and Finger Lakes Community College, Lawrence’s team also plans to create an open-sourced platform to facilitate cross-disciplinary research and education on vision sensor technology and cultivate the next-generation semiconductor workforce.

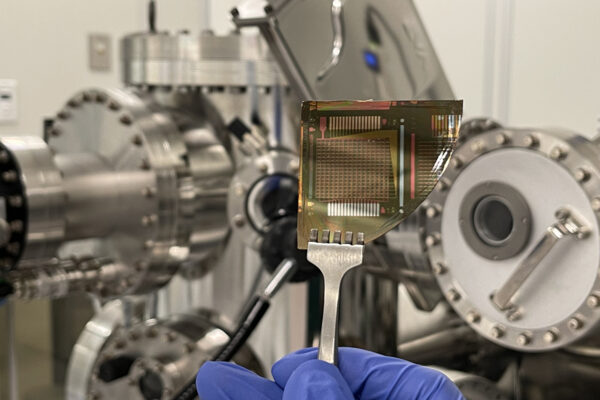

Advancing next-generation computer processors

Bae and collaborators Jeehwan Kim, at the Massachusetts Institute of Technology, Deji Akinwande, at the University of Texas at Austin, and Xiangfeng Duan, at the University of California, Los Angeles, will develop a new materials-based solution for next-generation computer processors. The team received a total of $1.8 million to support its efforts.

Bae’s group aims to create the next generation of computer processors by integrating incredibly thin 2D materials into monolithic 3D computer chips.

“Our key innovation is that we can grow very high-quality material on any substrate,” Bae said. “We can realize 3D electronics based on 2D material. That lets us fully integrate different functional components, each on its own 2D layer, into a single high-density chip.”

This significant innovation in the semiconductor industry could reduce production costs, boost performance and increase integration density, in addition to advancing our fundamental understanding of low-dimensional materials.

Yunjing (Dorothy) Wang, a lecturer in electrical and systems engineering at WashU, is collaborating with Bae on the educational plan and workforce development components of the project, which will involve high school, undergraduate and graduate students in training and research, preparing them for the workforce. Additionally, Bae and Wang plan to organize workshops, symposia and tutorials, as well as participate in international conferences to exchange technical expertise and enhance the project’s impact.

The team also intends to collaborate with semiconductor companies, aligning research efforts with industry needs, potentially translating these innovations into practical technologies, and ultimately paving the way for more powerful, efficient and cost-effective electronic devices that can meet the needs of information-driven applications.

Originally published on the McKelvey School of Engineering website.